What are Cold Pressed and Hot Pressed Saw Blades?

The sintered process is divided into cold pressed and hot pressed.

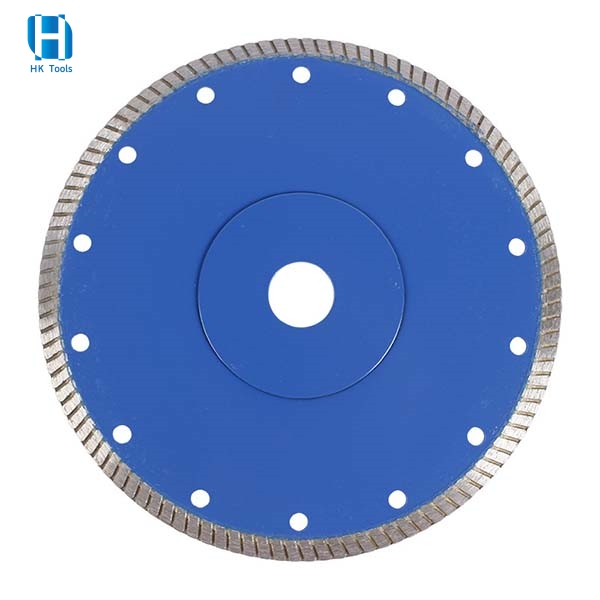

1. Hot Pressed Diamond Saw Blade.

First, the diamond particles and metal powder need to be mixed in a ball mill in a certain proportion to make them evenly distributed. Then the diamond mixture is loaded into the mold and pressed to make it initially formed, and then sintered under high temperature and high pressure conditions.

As the hot pressing diamond saw blade is carried out under high temperature and high pressure, the sintering density is high, the bond between diamond particles and metal matrix is more solid, the saw blade structure is more stable, the saw blade is not easy to be deformed during the cutting process, and the cutting precision is higher. Due to the fine control of the hot pressing process, the distribution of diamond particles in the saw blade is more uniform, and the wear resistance is good. In addition, the thickness of sintered process diamond saw blade tips is thinner, and the thickness of each tip is basically the same. The cutting friction is lower and the cutting speed is faster, with a production cycle of less than 15 minutes.

◇Advantages: Because the diamond particles of the hot pressed diamond saw blade are hard and the head is thin, its cutting efficiency is higher, the service life is longer, the replacement frequency is reduced during use, and the cost is reduced.

◇Disadvantages: The price is relatively higher than that of the cold pressed saw blade.

◇Applicable types: Suitable for high-strength and high-precision cutting tasks, such as large-scale construction projects, precision stone processing, etc.

2. Cold Pressed Diamond Saw Blade.

The cold pressing process is relatively simple and does not require complex equipment or high temperature and pressure conditions, resulting in low production costs. Since the production process does not require high temperatures, the requirements for diamond grains are lower and diamond grains of lower hardness are usually used. In addition, there is no high pressure pressurisation during the sintering process, and the distribution of diamond particles in the cutter head may be uneven, which may easily affect the service life of the saw blade. In addition, the control precision of the cold pressing process is relatively low, producing saw blades with usually thicker cutter heads, higher friction during the cutting process, and relatively slower cutting speeds. At the same time, the thickness of each blade head will have a slight deviation, and vibration may occur during the cutting process, affecting the cutting effect. Cold pressing has a large output and a long production cycle of several hours.

◇Advantages: simple manufacturing process, low production cost, and cheap price. The production process is simple, the production speed is fast, and the delivery time is short.

◇Disadvantages: Large-scale unified production, product quality cannot be guaranteed, and due to the hardness of diamond particles and the thickness of saw blades, the cutting accuracy, speed, and service life are poor.

◇Applicable types: Suitable for general cutting operations, such as home decoration, small construction projects, and other occasions where cutting accuracy and durability are not required.

In summary, hot-pressed and cold-pressed diamond saw blades have their own advantages in process and performance. Hot-pressed saw blades have superior cutting performance and durability due to their high-hardness diamond particles and precisely controlled saw blade thickness; while cold-pressed saw blades meet general cutting needs with their economic and widely applicable characteristics. Users should reasonably choose the appropriate diamond saw blade according to specific application scenarios and needs to achieve the best cutting effect and economic benefits.

You are also welcome to contact us to purchase samples for testing and deeply experience the characteristics of two different process saw blades!

Post time: Jun-07-2024