Products

Best quality HSS M42(Co8%) straight shank twist drill bits for metal stainless steel drilling

Product Description

HSS twist drill bit M42(8%Co) is the best drill bits in the word. It’s Rockwell hardness HRC65-67 degrees and must drilling metal <40 degrees, which is harder than M35 twist drill bits, more wear-resistant, smoother chip removal and more efficient.

The larger the diameter, the slower the required speed, generally suggestion 100-800R/MIN.For stainless steel, steel plate, cast iron, aluminum alloy drilling.

Notice: Don’t used to drill concrete, tile, wall, stone and other materials drilling. HSS twist drill bits are Used for 650W hand drill, table drill, milling machine.Lithium-ion drill has less power and is suitable for punching materials with low hardness. Punching more than 2mm add coolant to continue punching, is to extend the life of the drill bit.

|

Material |

HSSM42, HSSM35, HSSM2(6542), HSS4341, HSS4241 |

|

Process |

fully ground, edge ground/half ground, roll forged, milled |

|

Standard |

DIN338, DIN340, DIN1897, DIN1869 |

|

Split Point |

118°and 135° tip both available |

|

Stamping |

laser marking and (letter) stamping. |

|

Shank |

Straight shank(Tri-Flats shank,Hex shank,Round shank,Morse taper shank) |

|

Available Packing |

single sleeve packing, sandwich packing, blister packing, square plastic |

|

Surface Color |

black flute & golden shank, black flute & white shank, bright finished, |

|

Diameter Size |

0.5-20mm. 1/16"-1", A-Z, 1# - 90# |

|

Total Length |

2.5-140mm |

|

Features |

1.HSS m42 drill bits are more expensive than other drill bits, but if you regularly drill through metal, they are a good investment since they tend to last longer. |

Product Details

We have DIN338 standard all size HSS M42 twist drill bits.

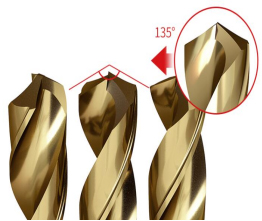

118° and 135° split points

The 118° point angle is mainly used for softer materials such as mild steel and cast iron.

The 135° split point is used for cutting hard steel, especially for deep holes that are more than 4 times the diameter of the drill bit. Using the 135° split point, cutting harder materials produces thicker chips, minimizing work hardening of the cavity.

Spiral fluted shank

Fully ground body construction. High flow spiral design for the fastest removal speed and for thick material

Straight shank

Straight shank for standard chuck,

less "walking" or "wandering."

The end of the shank is chamfered

to allow an easy and firm grip.

Special SST heat treatment of bronze

and surface.

HSS Twist Drill Bits RPM

Suggestions: Bigger diameters, slower RPM speed.

|

Twist Drill Bits Diameters(mm) |

RPM(R/Min) |

Application |

|

1mm-2mm |

3000-1800(r/min) |

|

|

2mm-3mm |

1800-1400(r/min) |

|

|

3mm-4mm |

1400-1000(r/min) |

|

|

4mm-5mm |

1000-800(r/min) |

|

|

5mm-6mm |

800-700(r/min) |

|

|

6mm-7mm |

700-600(r/min) |

|

|

7mm-8mm |

600-500(r/min) |

|

|

8mm-9mm |

500-400(r/min) |

|

|

9mm-10mm |

400-350(r/min) |

|

|

10mm-11mm |

350-300(r/min) |

|

|

11mm-12mm |

300-280(r/min) |

|

|

12mm-13mm |

280-250(r/min) |

|

|

14mm |

220(r/min) |

|

|

15mm |

200(r/min) |

Product Application

|

Material |

Suitable for drill holes | ||||||||

|

Stainless Steel |

Cast Plain |

Plain Carbon Steel |

Bronze |

Brass |

Copper |

Aluminium |

Plastics |

glass, tile floors, wall |

|

|

HSS4241 |

× |

√ |

× |

√ |

√ |

√ |

not good |

√ |

× |

|

HSS6542/M2 |

not good |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

× |

|

HSS Co/M35 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

× |

|

HSS Co/M42 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

× |

Our Advantages

-We have larger warehouse to shock products for delivery on time.

-We have professional sale and technology team to serve our customers to ensure your shopping experience

-Our products with best material HSS M42 to ensure our twist drill bits sharp and fast drilling ;

-Stable quality and widely use for hole drilling in hard material;

-Because our is factory, we can supply competitive price.

-The samples are free, and freight is collected. If we can have your order, we will decrease the freight cost from our first order.