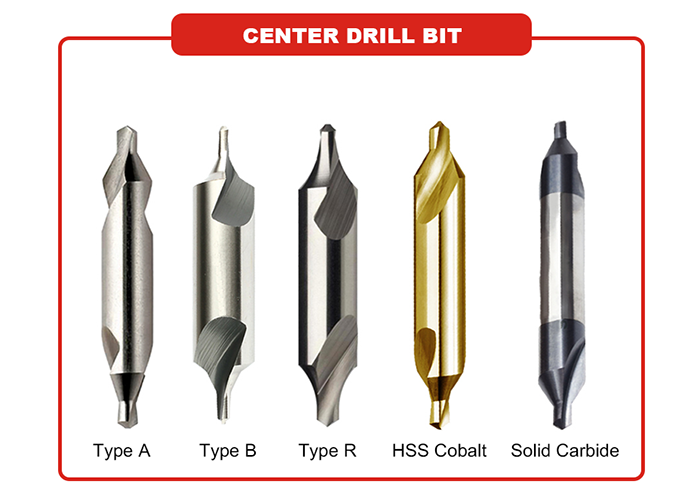

Types of Center Drill Bit

Center drill bit is a common tool in mechanical processing and plays an important role in actual production.

Center drill bit was first used in lathes to drill the center hole of shaft parts. With the increasing popularity of automation, it is more widely used in multi-functional CNC equipment. Its biggest function is to be used for prefabricated precise positioning of hole processing, guide twist drills to process holes, and reduce errors.

Center drills come in two common types, Type A (DIN 333-A) and Type B (DIN 333-B), based on the center drill angle.

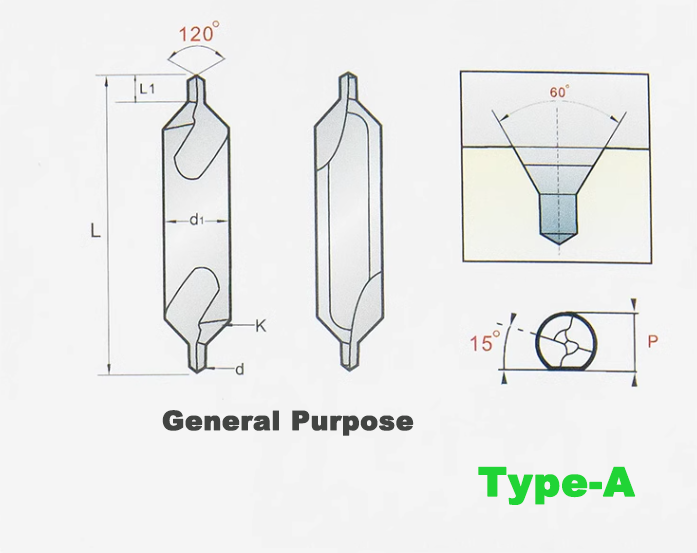

1.Type A center drill

It is a center drill without cone protection, suitable for processing A-type center holes. It only has a 60° cone hole and no additional protection measures, suitable for simple center hole processing.

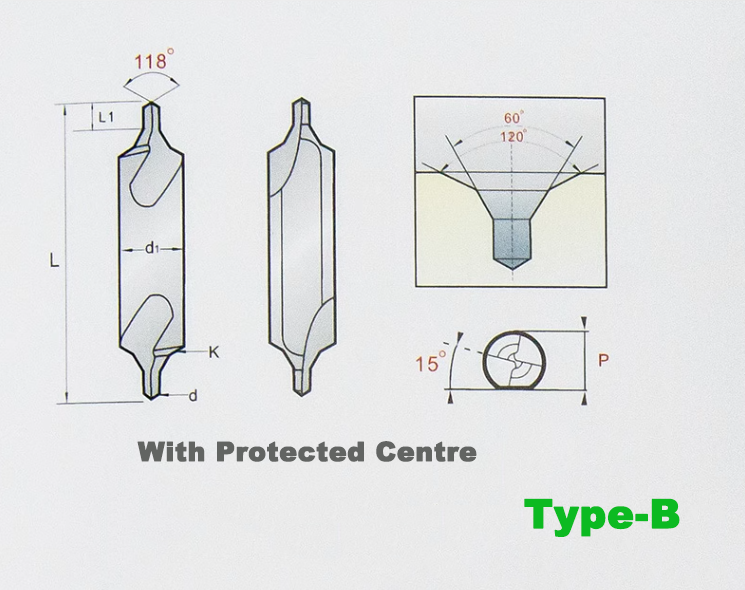

2.Type B center drill

It is a center drill with cone protection, suitable for processing B-type center holes. In addition to the 60° cone hole, it also has a 120° cone surface, called a protective cone surface, which is used to protect the outer edge of the 60° cone hole from being damaged. B-type center drills are mainly used for processing on lathes or machine tools to ensure stability and accuracy during processing.

There is also Type R center drill, which is suitable for processing R-type center holes. This is a specific type of center drill designed to meet specific processing needs.

Choosing the right type of center drill is crucial to ensuring processing quality and efficiency. Each type of center drill has its specific application scenarios and advantages, so when using it, you need to choose the right type according to the specific processing needs. For example, the B-type center drill is more suitable for use in situations where the outer edge of the tapered hole needs to be protected from damage due to its design of protecting the tapered surface, while the A-type center drill is more suitable for simple center hole processing.

Post time: Aug-23-2024