Products

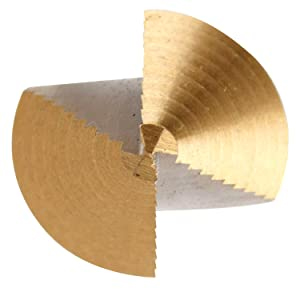

3PCS 4-12/4-20/4-32mm Metric Spiral Flute Step Drill Bit Set With Wooden Box

Product Features

1.HSS step drill bits are more expensive than other drill bits, but if you regularly drill through metal, they are a good investment since they tend to last longer.

2.No center punch is needed—the aggressive 135° and 118° Quick-Cut points are self-centering and penetrate quickly with less pressure. Will not "walk" or "wander".

3.Precision ground point, flutes, body, clearance and drill diameter for the ultimate in accuracy and performance.

4.Hex-shank drill bits design have a hexagonal shank that provides maximum surface contact with a drill chuck on handheld power tools. This prevents the bits from slipping in the chuck during drilling. Drill bits with a hex shank insert into a standard 3-jaw drill chuck or a drill chuck specifically designed for hex shanks.

5.Perfect Step Drill Bits suitable for drill holes in various material: within 3mm/0.12 inch (Iron Plate, Copper Plate, Aluminum Plate); within 5mm/0.2 inch (Wood, PVC sheet, Insulation Boards).

Not suitable for hard and brittle materials such as stainless steel, glass, tile floors, walls etc

Product Parameters

|

Step Drill Bits

|

|

|

Material

|

HSS 4241, HSS 4341, M2, M35

|

|

Surface Treatment

|

Bright finished, Tin-coated, Cobalt coated, Black-oxidized

|

|

Shank

|

Round Shank, Three-Side Shank, Hex Shank, Hex Shank With a Step

|

|

Flute

|

Straight Flute, Spiral Flute

|

|

Process

|

Fully Ground

|

|

Application

|

Aluminum, Iron, Carbon Steel, Stainless steel, Plastic, etc.

|

|

HSS4241 2mm Aluminum, Iron, 5mm Plastic

HSS6542/M2 5mm Aluminum, Iron, Carbon Steel, Plastic HSSCO/M35 5mm Aluminum, Iron, Carbon Steel, Stainless Steel, Plastic |

|

Product Highlights

Universal Design

The HEX shank is a great universal fit that will give you confidence while you work knowing that your drill bit is securely in place.

Engraved Sizes

Easily identify which size you need with the contrasted, laser engraved sizes inside the step drill bit flute size1/4”-1-3/8”.

Increased Cutting Speed

The split point tip is at 135 degrees which allows you to cut faster throughout multiple uses. This also ensures that you get sharp cutting on a wide variety of materials.

Recommended Drilling Speeds In Metal

Use the correct drill speed to ensure the ideal drill bit performance in the material being drilled.

|

Drill Size |

|||||||||||||

|

|

1MM |

2MM |

3MM |

4MM |

5MM |

6MM |

7MM |

8MM |

9MM |

10MM |

11MM |

12MM |

13MM |

|

STAINLESS STEEL |

3182 |

1591 |

1061 |

795 |

636 |

530 |

455 |

398 |

354 |

318 |

289 |

265 |

245 |

|

CAST IRON |

4773 |

2386 |

1591 |

1193 |

955 |

795 |

682 |

597 |

530 |

477 |

434 |

398 |

367 |

|

PLAIN CARBON STEEL |

6364 |

3182 |

2121 |

1591 |

1273 |

1061 |

909 |

795 |

707 |

636 |

579 |

530 |

490 |

|

BRONZE |

7955 |

3977 |

2652 |

1989 |

1591 |

1326 |

1136 |

994 |

884 |

795 |

723 |

663 |

612 |

|

BRASS |

9545 |

4773 |

3182 |

2386 |

1909 |

1591 |

1364 |

1193 |

1061 |

955 |

868 |

795 |

734 |

|

COPPER |

11136 |

5568 |

3712 |

2784 |

2227 |

1856 |

1591 |

1392 |

1237 |

1114 |

1012 |

928 |

857 |

|

ALUMINIUM |

12727 |

6364 |

4242 |

3182 |

2545 |

2121 |

1818 |

1591 |

1414 |

1273 |

1157 |

1061 |

979 |

NOTE: The faster the speed, the smaller the rotational requirement.