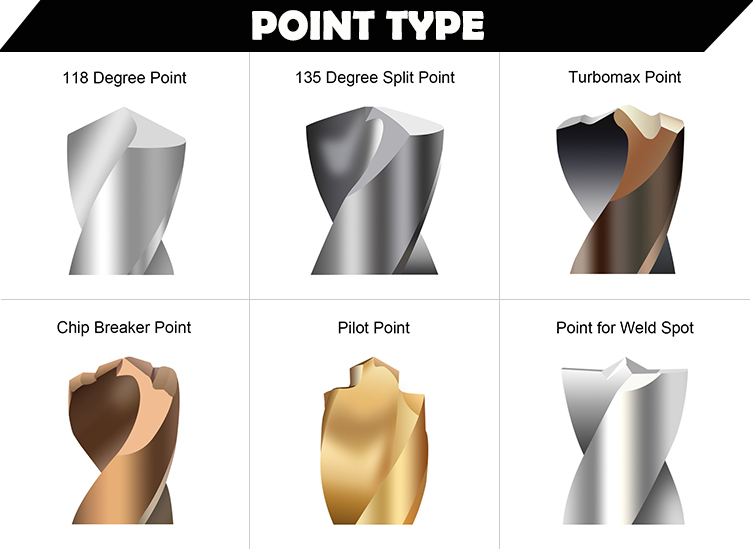

118° vs 135° Drill Bit Point Angles Explained

1.118 Degree Drill Bits:

-Versatility: 118 degree drill bits are widely used and considered versatile because they can be used for a variety of materials, including wood, plastic, and metal.

-Smoother Cut: The shallower point angle of 118 degree bits allows for a smoother and more precise cut. This is particularly useful for applications where a clean finish is desired, such as woodworking or drilling through softer materials.

-Reduced Heat and Wear: Due to the lower point angle, 118 degree bits generate less heat during drilling. This can be beneficial when working with temperature-sensitive materials or when prolonged drilling is required.

Additionally, they tend to experience less wear, resulting in a longer lifespan.

2.135 Degree Drill Bits:

-Hard Material Capability: 135 degree drill bits are specifically designed for harder materials, including stainless steel, cast iron, and other tough alloys. The steeper point angle allows for a more aggressive cutting action, making them suitable for drilling through these challenging materials.

-Durability: 135 degree bits are generally more durable and resistant to wear compared to 118 degree bits. This is particularly important when drilling through harder materials that can quickly dull or damage less robust drill bits.

-Stronger Cutting Action: The steeper point angle of 135 degree bits provides a stronger cutting action, allowing them to bite into the material more effectively. This can be advantageous when working with tough or dense materials that require extra force to penetrate.

It's important to note that while these general characteristics apply to most 118 and 135 degree drill bits, there may be variations in quality and performance depending on the specific brand and design. It's always recommended to choose drill bits that are suitable for the material you'll be working with and follow manufacturer guidelines for optimal results.

Post time: Nov-17-2023