Find out what a Brad Point Drill Bit is and how to use it

What is a brad point bit?

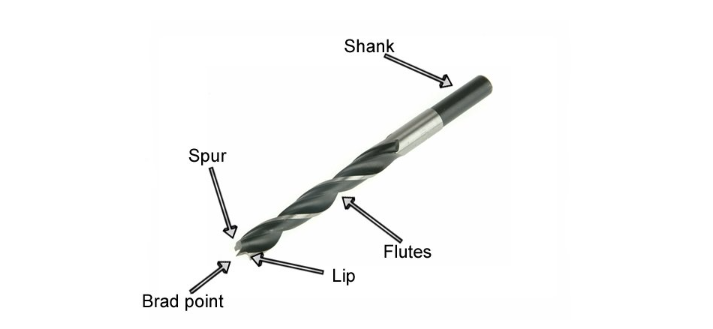

Brad Point Drill Bit, also known as a wood drill bit, is a tool designed to make precise, clean holes in wood. While a twist drill bit may slip on the wood fibers before you start drilling, Brad-Point Drill Bit allows you to drill holes with precision and accuracy.

This is thanks to the tool's name: BRAD POINT. The sharp brad digs into the wood surface, holding the drill bit in place and ensuring the hole is drilled precisely.

The spikes on the drill bit's circumference cut cleanly through the wood fibers, while the horizontal lip shears out the material as the drill moves through the workpiece. In practice, this means that the drill bit cuts the outside of the hole first.

Due to their physical properties, these bits are sometimes called lip and spur bits or W-point bits.

How does brad point bit work?

The first part of the drill that comes into contact with the wood is the twist drill bit. The twist drill bit bites into the wood grain, preventing the drill bit from moving.

As the drill bit descends, the spikes move along the edge of the drill hole, cutting the circumference of the hole. As it drills through the wood, the spikes neatly shear the fibers of the wood so they don't bend under the pressure.

The lip of the drill bit soon contacts the surface of the material and begins to cut away any waste material left by the spikes. This waste material is pushed up through the grooves and out of the drill hole.

As the spikes continue to rotate, they make a very clean cut all the way down the edge of the hole, continuing to sever the fibers and preventing splinters from forming in the fibrous material.

This also applies to tungsten carbide and polycrystalline diamond drill bits that cut through Kevlar-reinforced materials. Kevlar is fibrous, so each time the drill bit reaches a layer of Kevlar, the spikes make a clean cut and prevent fuzz (fibers that wear or get stuck on the drill bit and protrude into the drill hole) from forming.

If the fibers are not cut correctly, the exposed fibers in the nap can get caught on bolts or screws inserted into drilled holes on the assembly line, which can cause the layers of the composite to pull apart. This is called delamination.

Click to see a video on how to use it:Brad point drill bit

Post time: Jul-05-2023