Method of Choosing the Best Drill Bits for Your Drilling Work

In mechanical processing, drilling processing accounts for about 1/5 of the total processing volume, and drilling processing accounts for about 30% of the total hole processing volume. When buying drill bits, there are drill bits of different colors, different materials, and different processes.

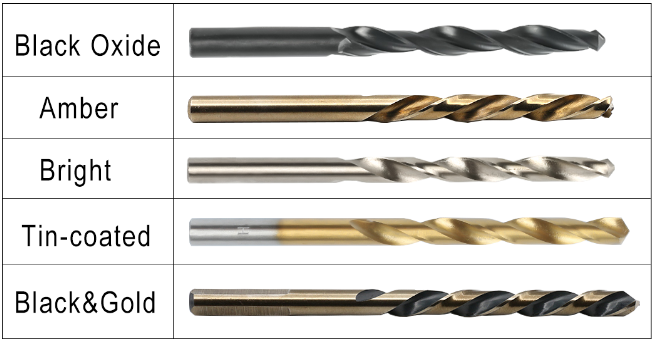

1.Choosing the drill bits according to the appearance of drill bits Color and appearance.

For example, Is there any relationship between the drill bit's color and its quality? The different colors are mainly due to different processing techniques.

High-quality fully ground high-speed steel drill bits are often found in white. Of course, the rolled drill bit can also be whitened by finely grinding the outer circle. What makes them high quality is not only the material itself, but also the quality control during the grinding process. It is quite strict and there will be no burns on the tool surface. The black ones are Nitride drill bits. It is a chemical method that places the finished tool in a mixture of ammonia and water vapor and performs heat preservation treatment at 540~560C° to improve the durability of the tool. Most of the black drill bits currently on the market are only black in color (in order to cover up burns or black skin on the surface of the tool), but the actual use effect has not been effectively improved.

2.Choosing the drill bits according to the material of drill bits

The market's common materials used for drill bits are 4241/4341/9341/6542/M35/M42, and their performance increases sequentially.

If you want to know more, please see: Drill Bit Material Comparison & Types-Choose The Right One

3.Choosing the drill bits according to the producing processes of drill bits

There are three processes for producing drill bits: rolling, milling, and grinding.

The central processing techniques of twist drill bits are spiral groove processing, heat treatment, and sharpening. Because heat treatment and subsequent grinding processes are the same, the main difference lies in forming the twist drill's working part.

Milling Process: Use a forming milling cutter to mill the required spiral groove shape on the unhardened twist drill blank. The milling method has an extensive processing range, mainly processing 10 to 70 mm twist drills. The disadvantage is that the tool's cost is high, the processing time is long, and the final shape is processed before heat treatment.

Rolling Process: Rolling four fan-shaped plates on the heated blank to form the shape of the drill bit. Compared with the milling method, the drill bit manufactured by plastic deformation has lower accuracy. The advantage of this method is mainly that it saves the raw materials for manufacturing twist drills and is therefore more economical.

Grinding Process: High-speed grinding can reduce the cutting force and significantly improve the surface quality, and reduce Shape error.Compared with the milling method, the grinding method can significantly reduce the single-piece working hours, and the quality is high and stable.

Post time: Jun-01-2023