PZ vs. PH Screwdriver Bits: Key Differences and Uses Explained

Screwdriver bits come in a variety of shapes and sizes to accommodate different types of screws. Among these, PZ (Pozidriv) and PH (Philips) bits are two of the most commonly used types, each designed for specific tasks. Understanding the differences between them and knowing when to use each can significantly improve your work efficiency and ensure the safety and durability of your projects.

1. What is the Difference Between PZ and PH?

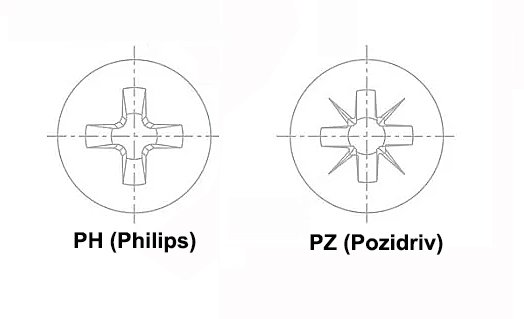

The main difference between PZ (Pozidriv) and PH (Philips) lies in their design, which affects how the bit interacts with the screw head.

- PH (Philips) Screwdriver Bits:

- The PH bit features a simple cross-shaped design with four contact points.

- It was originally created to prevent the bit from slipping out of the screw while in use, offering a more secure fit.

- The shape of the cross is designed with a slight cam-out feature (i.e., the bit will slip out if too much force is applied), which helps prevent over-tightening and damage to the screw or the material.

- PZ (Pozidriv) Screwdriver Bits:

- The PZ bit is an improved version of the PH design. It features not only the same cross pattern as the PH but also additional smaller ribs between the main cross points.

- This design provides extra grip and reduces the likelihood of cam-out.

- The Pozidriv system is known for delivering higher torque, making it more efficient in high-torque applications without damaging the screw or bit.

2. Which One to Choose: PZ or PH?

Choosing the correct bit is crucial for the effectiveness and longevity of your work. Here's when to use each:

- Use PH (Philips) Screwdriver Bits:

- For standard screws, commonly found in household applications and light construction.

- When you don’t need to apply excessive torque, as the PH system is more prone to cam-out.

- Ideal for softer materials like wood and plastic, where minimal force is needed.

- Use PZ (Pozidriv) Screwdriver Bits:

- For heavy-duty tasks, particularly in high-torque applications such as automotive repairs, furniture assembly, or electrical installations.

- When you need more control and a more secure grip on the screw, especially for harder materials like metal or thick wood.

- Recommended for high-volume work, where increased durability and efficiency are needed.

3. Applications of PZ and PH Screwdriver Bits

- PH (Philips) Applications:

- Construction: Basic wood screws, drywall screws, and light-duty materials.

- Home Appliances: Electronics and other consumer goods typically use Philips screws for assembly.

- Furniture Assembly: Often used in flat-pack furniture assembly, where torque is not as high.

- PZ (Pozidriv) Applications:

- Automotive: More common in automotive and machinery work, where screws need to withstand high torque without slipping.

- Electrical: Used for installing electrical outlets, switches, and other components that require a secure connection.

- Heavy-duty Construction: For decking, structural woodwork, and any other application involving dense materials.

4. Conclusion

Understanding the differences between PZ and PH screwdriver bits is crucial for any handyman or professional worker. Using the correct bit ensures you can work faster, more efficiently, and with greater precision. The PH system is ideal for lighter tasks and general applications, while the PZ system excels in high-torque, heavy-duty work. Make sure to match the bit type with the corresponding screw to prevent damage to the material and the bit.

Choosing the right tool for the job is key, and with the right bit in hand, you can work smarter, not harder.

Post time: Feb-28-2025