The Differences Between T41 And T42

T41 and T42 refer to different types of abrasive cutting wheels, typically used for cutting metal, stone, or other hard materials. While they may appear similar, they are designed for slightly different applications due to variations in their structure and cutting capabilities.

Here’s a breakdown of the key differences between T41 and T42 cutting wheels:

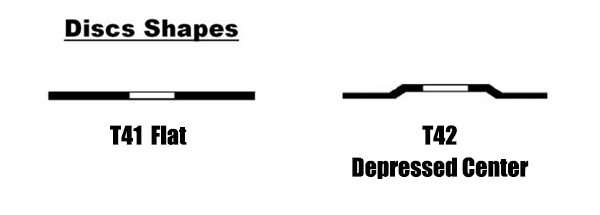

1.Shape

T41 Flat Cutting Disc, it has a flat surface with no raised center or hub. It is designed for straight cuts where the wheel cuts perpendicular to the workpiece.

T42 Depressed Center Cutting Disc has a recessed or depressed center that allows the cutting disc to be mounted at an angle. Ideal for cutting at an angle and can be used for cutting and light grinding tasks.

2.Applications

The T41 flat disc is primarily used for making straight, precise cuts on materials such as metal, stainless steel or stone. Ideal for jobs that require straight cuts and no angles.

The T42 depressed centre disc is more versatile and can be used for both cutting and light grinding due to its angled design. It is typically used when the user needs to cut at an angle or perform light surface grinding. The design provides better clearance when cutting or grinding, reducing the risk of the tool or disc contacting the work surface.

Summary

The T41 cutting disc is suitable for light to medium-duty cutting tasks, while the T42 center cutting disc is designed for heavy-duty applications. Choosing the right cutting disc is essential to ensure safe and efficient cutting and grinding. With the right cutting disc, you can achieve precise and accurate cuts and save time and money in the long run.

Post time: Oct-11-2024