What is High Speed Steel?

High-speed steel (HSS or HS) is a subset of tool steels, commonly used as cutting tool material.

It is often used in power-saw blades and drill bits. In addition, it is often used in bowl gouges and skew for woodturning.It is superior to high-carbon steel tools in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high-speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above 60 Rockwell C) and abrasion resistance compared with common carbon and tool steels. --Quoted From" https://en.wikipedia.org/wiki/High-speed_steel"

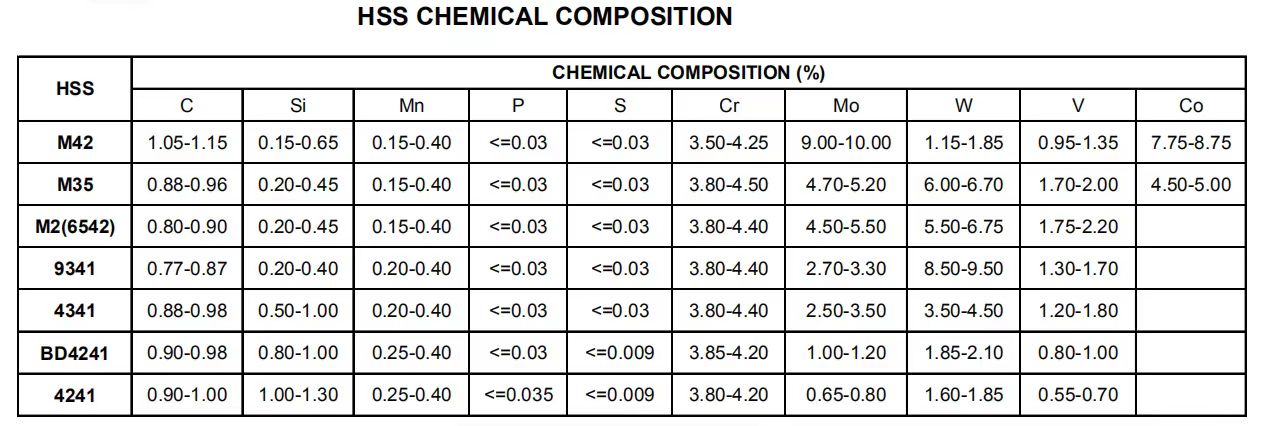

A sample of alloying compositions of common high speed steel grades (by %wt)(impurity limits are not included)

M2 is the most widely used industrial HSS. It has small and evenly distributed carbides giving high wear resistance, though its decarburization sensitivity is a little bit high.It is usually used to manufacture a variety of tools, such as drill bits, taps and reamers.

M35 is similar to M2, but with 5% cobalt added. M35 is also known as Cobalt Steel, HSSE or HSS-E. It will cut faster and last longer than M2.

M42 is a molybdenum-series high-speed steel alloy with an additional 8% cobalt.It is widely used in metal manufacturing industries.

If you want to know which material is suitable for different materials, please click: Drill Bit Material Comparison & Types-Choose The Right One to check.

HKTools has many years of research experience in the process performance, strength and toughness coordination of metal materials. If you are looking for a professional HSS DRILL BIT MANUFACTURER, HKTools will be your best choice.JUST CONTACT US!

Post time: Apr-26-2024