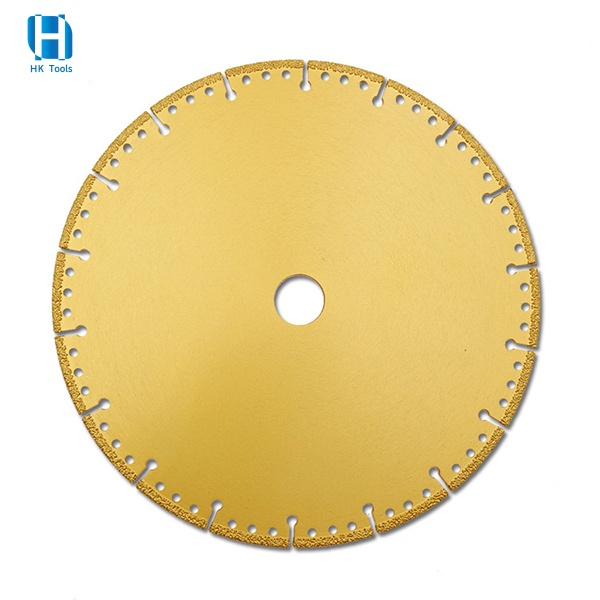

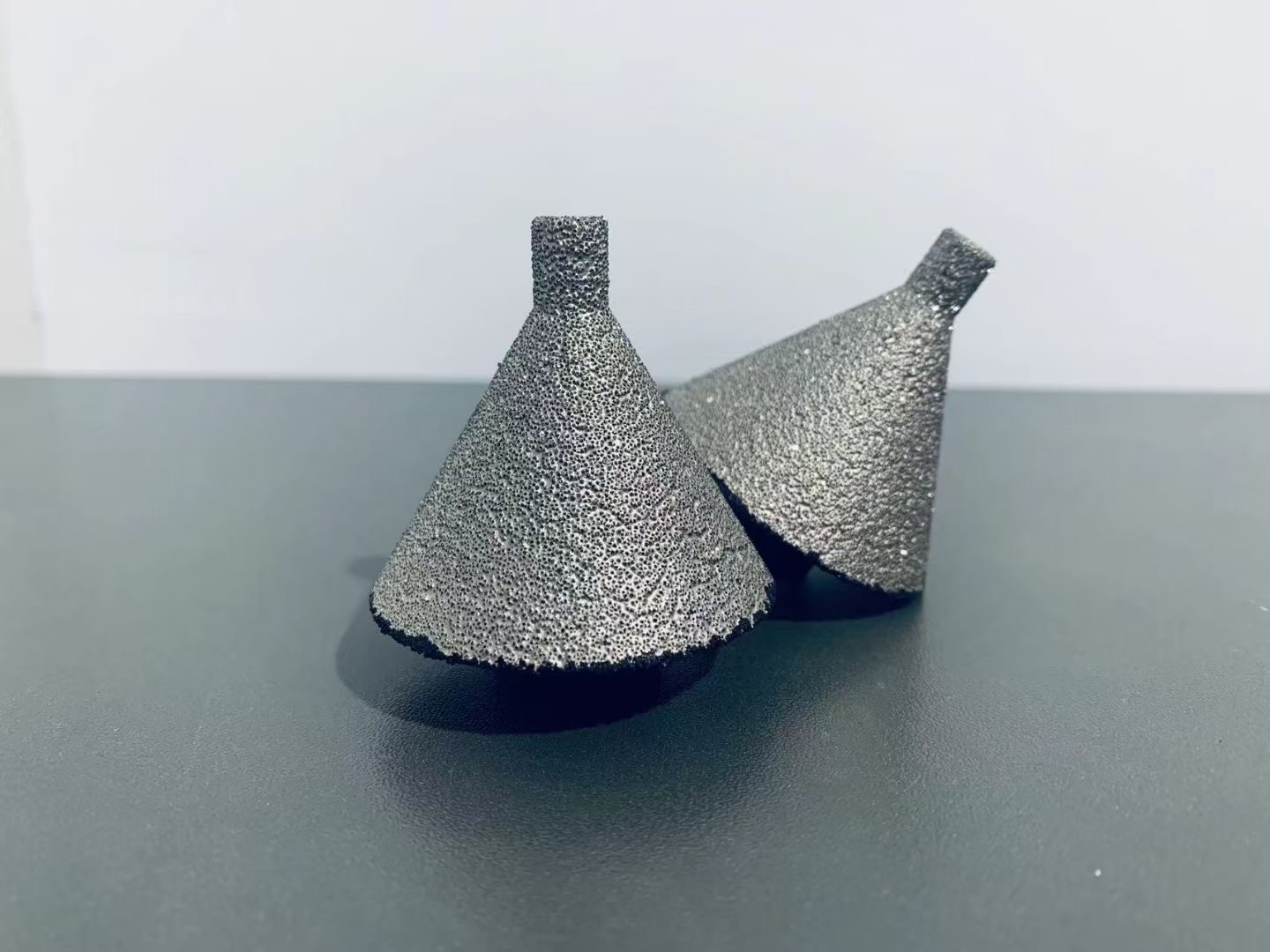

What are Vacuum Brazed diamond tools?

Vacuum brazed diamond tools are valued for their high performance, durability, and versatility in cutting, grinding, and drilling hard and abrasive materials.

Here's how vacuum brazing works:

•Diamond particles: Synthetic diamonds, known for their hardness and durability, are used as the cutting or grinding material in these tools. These diamond particles come in various sizes and shapes depending on the application requirements.

•Metal matrix: The diamond particles are bonded to the tool's surface using a metal matrix. This matrix is typically made of materials such as nickel, bronze, or other alloys that can withstand the high temperatures generated during the brazing process.

•Vacuum brazing process: In the vacuum brazing process, the diamond particles and the tool's surface are placed together in a vacuum chamber. The chamber is then heated to high temperatures, typically around 1000°C to 1200°C, using induction heating or another method.

•Brazing alloy: As the temperature rises, the brazing alloy melts and flows into the gaps between the diamond particles and the tool's surface. The vacuum environment ensures that there is no oxidation, which could weaken the bond between the diamond and the tool.

•Cooling and solidification: After the brazing alloy has filled the gaps and formed a strong bond, the vacuum chamber is cooled down, allowing the brazing alloy to solidify and permanently attach the diamond particles to the tool's surface.

The resulting vacuum brazed diamond tools offer several advantages:

♢High cutting efficiency: The hardness and sharpness of the diamond particles allow for fast and precise cutting, grinding, or drilling of hard materials such as stone, ceramics, glass, and composites.

♢Longevity: Vacuum brazed diamond tools have a long service life due to the strong bond between the diamond particles and the tool's surface, resulting in reduced downtime and maintenance costs.

♢Versatility: These tools can be designed in various shapes and sizes to suit different applications, making them versatile for use in different industries and tasks.

♢Consistency: The vacuum brazing process ensures a uniform distribution of diamond particles on the tool's surface, resulting in consistent performance throughout the tool's lifespan.

Post time: Jun-14-2024